SESSION 6

PLASMA DIAGNOSTICS

| Chairman: | J.Amouroux

V.Sember

|

ENTHALPY PROBE DIAGNOSTIC STUDFY OF THE SUPERSONIC INDUCTION PLASMA JET

M. Hollenstein1, M. Rahmane1.a and M.I. Boulos1

1 Plasma Technology Research Centre (CRTP), Dept. de génie chimique, Université de

Sherbrooke, Sherbrooke, Québec, Canada, J1K 2R1

a Present address: Dept. de physique, Fac. des Sciences et Techniques, Université

Hassan II, Mohammadia, 20650, Maroc

INTRODUCTION

Although probe techniques have been available for many years for plasma diagnostics,

they have been getting a wider acceptance over the past ten years. The most important of

theses are the langmuir and enthalpy probes. Enthalpy probes can be used for the

simultaneous measurement of the locale specific enthalpy, velocity and composition of

the plasma. Their main advantage is the simplicity of the technique, and its possible use

for the simultaneous measurement of multiple plasma parameters with a generally

acceptable special resolution. Its main limitation, however, is that it is an intrusive

technique, with the probe inevitably causing a local perturbation of the flow. Enthalpy

probe techniques can not be used either for time-resolved measurements. A brief

description is given in this paper of the use of enthalpy probes for the characterization of

a supersonic induction plasma jet.

BASIC CONCEPTS

A schematic of the setup used for enthalpy probe measurements in an induction plasma

jet is given in Figure 1. This consists essentially of a triple wall probe cooled by a high

pressure, deionized, closed loop, water circuit. The specific enthalpy of the plasma is

determined through a measurement of the difference between the heat load on the probe

cooling circuit under sampling and tare conditions.

where mw is the cooling water flow rate, Cpw is the specific heat for the water, mg is

the sample gas flow rate. DTsample and DTtare are the temperature rise of the cooling

water under sampling and tare flow conditions. Knowing the specific enthalpy of the

plasma, ho, and its composition, xo, the plasma temperature can be calculated using

available thermophysical data. From a measurement of the dynamic pressure on the

probe tip, the local plasma velocity can be calculated as follows:

For incompressible flow:  where (Po-

where (Po- )

is the measured

dynamic pressure, and r is the local plasma density computed at the local plasma

temperature, To, and composition, xo. )

is the measured

dynamic pressure, and r is the local plasma density computed at the local plasma

temperature, To, and composition, xo.

For compressible flow, an interactive procedure has to be used for the solution of the

following equations relating the ratio of the local impact pressure, Po to the chamber

pressure,  , with the local Mach Number, Mo, with , with the local Mach Number, Mo, with  with with

, R=universal gas constant, and To the absolute plasma temperature. , R=universal gas constant, and To the absolute plasma temperature.

SUPERSONIC INDUCTION PLASMA TORCH

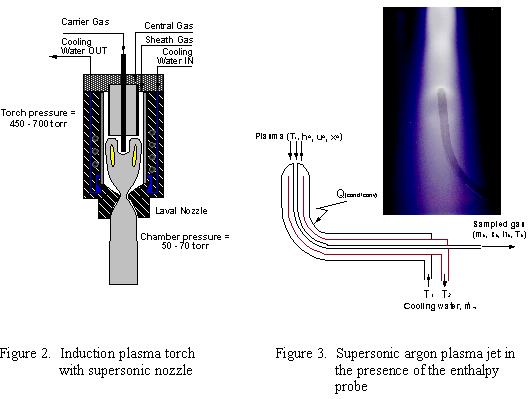

Supersonic flow is achieved using a standard PL-35 Tekna plasma torch through the

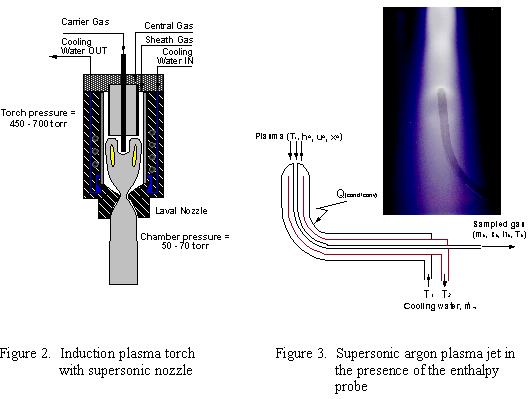

addition of a Laval type nozzle at the exit of the torch as shown in Figure 2. A

photograph of an argon plasma jet in the presence of a 4.78 mm diam. Enthalpy probe is

given in Figure 3.

TYPICAL RESULTS

Typical radial profiles obtained at an axial location, z = 25 mm, downstream of the

nozzle exit, for the local plasma temperature, velocity, Mach number and dynamic

pressure, are given in Figure 4. These were obtained with a Mach 1.5 nozzle with a

throat diameter of 12.8 mm and an expanded jet diameter of 13.8 mm. The plasma gas

was in this case an Ar/H2 mixture with 2% vol. H2. The plate power of the r.f. power

supply was 25 kW, with a corresponding r.f. power coupled into the plasma of about

16.25 kW. The absolute pressure in the discharge chamber was 17.1 kPa with the back

pressure in the torch cavity of 36.3 kPa. It is noted that a maximum centerline Mach

number of 1.0 is obtained on the centerline of the torch with a corresponding local plasma

velocity of almost 1500 m/s. The local plasma temperature in this region was about

5500K. Measurement carried out for the same plasma gas mixture with a Mach 3.0

nozzle, at an axial location, z = 17 mm, from the nozzle exit, gave rise to an increase of

the local Mach number on the axis of the discharge to 2.0 with a corresponding local

plasma velocity of 2000 m/s and a centerline temperature of 2500K.

TRANSIENT PHENOMENA IN D.C. TORCHES

J.F. Coudert

SPCTS – Equipe Procédés des Traitements de Surface, UMR n°6638, Faculté des Sciences

123 Avenue Albert Thomas, 87060 Limoges Cedex – France

D.C. plasma torches have been involved for many years in industrial

applications such as welding, cutting or deposit elaboration by plasma spraying or

plasma assisted vapor deposition.

These techniques use specific properties of plasmas produced by D.C. arcs,

where high temperature (up to 25000 K) and high flow velocities (up to few km/s) are

available. A considerable amount of experimental work was devoted, in the past, to

characterize the properties of arc jets as a function of arc current, torch design or

configuration, plasma forming gas thermophysical properties and flowrate. In the

same time models approached more and more accurately the behavior of arc jets,

testifying of a real advance in both knowledge and understanding of the different

implicated processes and mechanisms.

Nevertheless, mainly because of experimental difficulties, transient

phenomena due to arc instabilities have been less intensively studied and their interest

has only been underlined the last decade, altough they have been mentionned more

than thirty years ago.

Due to the extraordinary progress accomplished in the field of instrumentation,

new diagnostic techniques have raised, accompanied by powerful signal processing

methods which are now easy to apply thanks to the development of computers and

associated softwares.

It has been experimentally demonstrated in plasma torches that the arc is

submitted to gas dynamic forces which give rise to different modes of instabilities

among which to major cases can be distinguished. The first one is the so-called

«take-over» mode, characterized by rather low fluctuations of arc voltage compared

to the mean value, the second one being the «restrike» mode, for which the

fluctuations of arc voltage are about the same in amplitude than the mean value. The

restrike mode is clearly identified as the result of the stretching of the arc by the cold

gas flow, followed by electrical breakdown of the cold gas layer which give rise to a

new arc-anode attachment. The stretching-rearcing sequences is repeated at a

frequency which is governed by experimental conditions and give a saw tooth-shaped

voltage signal, which analysis provide clear informations about the arc dynamics.

The fluctuation of arc length generate strong voltage variations which are

correlated to the electrical power supplied to the gas and, as a consequence, to the

variations of the arc jet temperature and velocity.

The amplitude and frequency of voltage fluctuations can be related to the torch

working and geometrical parameters and dimensional analysis allow to establish

reliable semi-empirical correlations. Temperature and velocity distributions are

strongly correlated to the torch working conditions and the resulting fluctuations. It

will be illustrated for different operating conditions of a D.C. spray toch.

CHARACTERISTICS OF TURBULENCE OF THE BOUNDARY LAYER

BETWEEN PLASMA JET AND AMBIENT GAS

INVESTIGATED BY ELECTRIC PROBES

Vladimir Kopecky, Milan Hrabovsky and Milos Konrâd

Institute of Plasma Physics, AS CR, Za Slovankou 3, CZ-182 21 Prague 8, Czech Republic

INTRODUCTION

Interaction of plasma jets with an ambient atmosphere play an important role in plasma processing applications, e.g. in plasma spraying or treatment of hazardous waste. Entrainment of cold gas in thermal plasma jets was studied by several methodsl-3. It has been shown in the foregoing authors papers4-5 that the application of the array of several electric probes is a relatively simple and efficient tool for local investigation of structure of flow field in the thermal plasma jets. Electric probes measurements are used in this paper for the investigation of characteristics of turbulence arising in the interaction zone of the plasma jet with the ambient air.

|

EXPERIMENTAL SETUP

The experiment was performed with the plasma jet generated by plasma torch with water stabilized electric arc. The total power of the torch was varied in the range 90 - 200 kW. Thus, the development of turbulence was investigated for mean exit plasma velocity in the range 1700 to 4200 m/s6. The array of 6 probes made of Mo wire with diameter 1 mm and length 1 mm was moved through the plasma jet with velocity less than 1.5 m/s at different positions downstream of torch exit. The probes were positioned 3-7 mm apart with various mutual arrangements. The probes were negatively biased and were operated in ion collecting part of the probe characteristics. They were connected to the source of biasing voltage through the resistor. The values of the resistance and the voltage were adjusted to obtain high sensitivity of the probe signal to plasma properties. Strongly fluctuating probe signals were obtained when plasma disturbances flowed along the probes tips. The maps of the probe current contours in coordinates corresponding to radial position and time represent the structure of the plasma flow.

RESULTS

Plasma flow structure in the jet was investigated for various arc currents and various plasma flow velocities. Fig. 1 shows an example of a map of the same probe currents in the boundary zone of the jet. Almost periodic structure of the boundary was observed along the jet with regions of cold gas entrained into the plasma jet and regions of plasma propagating into the surrounding gas. From these maps obtained by statistical analysis of measured probe signals at different positions along the jet following characteristics of flow in the jet bouridary were determined (Fig. 1): mean axial distance of regions of cold gas in the jet L=vtL, mean axial dimension of cold gas regions D=vtD and mean depth H of entrainment of gas into the jet. The velocity v was derived from the shift of signals of two probes located in different axial positions.

Characteristic dimensions L, D and H were dependent on arc current, i.e. on plasma flow velocity which is determined by arc current, and on axial position in the jet. Fig. 2 shows the dependence of ratio of the depth H to the mean radius of the jet R on the distance from the nozzle exit for two values of arc current.

It can be seen that the depth of entrainment H is larger for smaller arc currents, i.e. for lower temperature and energy content in the jet and for lower flow velocity. The characteristic dimensions of the entrainment rapidly increase with the distance form the torch exit.

ACKNOWLEDGEMENT

Financial support from the Grant Agency of the Academy of Sciences CR under project No. A1043804/1998 and from the Grant Agency of the Czech Republic under project No. 102/98/0813 is gratefully acknowledged.

|

REFERENCES

- Pfender E., Fincke J., Spores R.: Plasma Chem. and Plasma Proc. 11 (4), 1998, 529.

- Russ S., Pfender E., Strykowski P.J.: Plasma Chem. and Plasma Proc. 14 (4), 1994, 425.

- Fincke J.R., Chang C.H., Swank W.D., Haggard D.C.: Int. J. Heat Mass Transfer 37 (11), 1994, 1673.

- Kopecky V.: Electric probes investigation of turbulence in the interaction zone of the plasmajet with the ambient air. 1998 ICPP&25th Conf. on Contr. Fusion and Plasma Physics, Praha, ECA Vol. 22C, 1998, 2643 - 2646.

- Hrabovsky M., Konrâd M., Kopecky V.: Investigation of structure of turbulent boundary layer between thermal plasmajet and ambient air. 5th European Conference on Thermal Plasma Processes, St. Petersburg, 1998 (in press).

- Hrabovsky M., Konrâd M., Kopecky V., Sember V., Processes and properties of electric arc stabilized by water vortex, IEEE Trans. on Plasma Science 25 (1997), No. 5, pp. 833-839.

NUMERICAL AND EXPERIMENTAL STUDY OF MICROSCOPIC PARTICLES DISTRIBUTION UNDER CORONA DISCHARGE :

CASE OF WIRE-CYLINDER ELECTROSTATIC PRECIPITATOR

Mohamed Khalij, Nadjib Semmar and Marie-Odile Rigo

Laboratoire Universitaire de Mécanique et d'Energétique de Nancy

Faculté des Sciences,

Université Henri Poincaré, F-54506 Vandoeuvre-lès-Nancy, France

The study of microscopic particles behaviour under corona discharge was earlier based on

several basic concepts. More particularly, DC corona discharge was investigated by the way of

developing electrostatic precipitators1-3 (ESP) employed in air and gases cleaning processes.

Inside one stage ESP, microscopic particles are charged both by diffusion and by field charging

mechanisms, and then, collected on the electrode of opposite sign. Design of ESP's is usually

based on the Deutsch formula for turbulent flows in the case of instantaneous mixing. But,

when focus is on space distribution (local concentration of particles) in a given geometry, one

should resolve Electro-Hydro-Dynamic equations stated in the general case of dense flows4. In

the case of dilute flows, the appropriate convection-diffusion equation is considered to draw

the particle concentration field.

In this work, the convection-diffusion equation is resolved in the case of wire-cylinder

configuration, using realistic boundary conditions5-7. A finite differences method is then used to

compute the particle concentration field (fig.1) versus the axial position (z* = z/R), and the

particle concentration gradient (fig.2) versus the radial position (r* = r/R), considering the

geometric particle diameter (dP) as a parameter. This last figure, shows a maximum of the

gradient in the range r* = 0.15 to 0.3. Furthermore, the maximum of the fractional gradient

moves with respect to particle size (dP) and radius position (r*) depending on the electrical

charging mechanism. When the diffusion mechanism becomes powerless, the strength of the

electrical force is relatively reduced and consequently the maximum of fractional gradient

decreases. In the range of sub-microscopic particles, the tendency is opposite due to the

presence of both charging mechanisms. Notice that the minimum corresponds to 0.2 µm and

not to 0.1 µm.

In order to verify the assumption of dilute flow (no particle-particle interaction and no

coalescence phenomenon when treating atmospheric aerosols), the particle size distribution is

computed using the same numerical code. The experimental distribution is obtained on a

laboratory ESP (radius R = 17 mm and length Z =1020 mm for the collection electrode, and

0.15 mm radius for the wire electrode) using an optical counter probe under isokinetic

conditions (Re~9000, U = 4.2 m.s-1). Electrostatic conditions are : 11 kV for the wire

discharge voltage and 8 mA/m2 ionic current density. As illustrated on fig.3, comparison

between numerical and experimental results tends to confirm the previous assumption over the

range [0.5 - 2.0 µm].

|

|

|

Fig.1 : concentration field versus axial position z*

|

Fig.2 : concentration gradient versus radial position r* at z* = 10 (z = 10R).

|

| |

Fig.3 : Bar graph of both numerical and experimental particle size distribution

|

REFERENCES

- Parker C. Reist, Aerosol Science and Technology, McGraw-Hill, 2nd edition, 1993.

- Ogawa A. , Separation of particles from air and gases, CRC Press, 2nd printing, 1985.

- Williams J. C. and Jackson R., The motion of solid particles in an electrostatic precipitator,

Interaction Between Fluids and Particles, Instn. Chem. Engrs., London, pp. 282-288, 1962.

- Yamamoto T., Verkoff H.R., Electrohydrodynamics in an Electrostatic Precipitator. J.Fluid

Mech., 108, 1-18, 1981.

- Leonard G. L., Mitchner M. and Self S. A., Particle transport in electrostatic precipitators,

Atmospheric Environment, Vol. 14, pp 1289-1299, 1980.

- Shaughnessy E. J., Davidson J. H., and Hay J. C., The fluid mechanics of electrostatic

precipitators, Aerosol Science and Technology, Vol. 4, pp. 471-476, 1985.

- Li Enliang, Wang Yingmin, and Raper J. A., Study of gas velocity distribution in

electrostatic precipitators, Aerosol Science and Technology, Vol. 12, pp. 947-952, 1990.

ANALYSIS OF THE STABILITY OF DC PLASMA GUN USING TERNARY GAS MIXTURES Ar-He-H2

S. Janisson, , A. Vardelle (*), J.F. Coudert, P. Fauchais (*), E. Meillot

CEA Le Ripault - BP16 - 37260 Monts - France

(*) Equipe "Plasma Laser Matériaux", ESA CNRS 6015, Université de Limoges, 123 Avenue Albert Thomas, 87060 Limoges - France

In order to obtain deposit with the desired properties, the influence of plasma spraying

parameters on the flow and the coating was often studied. Nonetheless, if a lot of parameters (arc

current, total gas flow rate, gas composition) can be kept constant during the spraying, it is not the case of the arc voltage, which can be influenced by two phenomena. The first one is the electrode

erosion (which can be reduced by the use of Ar/He/H2 gas mixtures) resulting in a decrease of the

plasma momentum and a variation of the particle behavior in the plasma jet. This variation can be

corrected by increasing the power of the torch (arc current or the percentage of hydrogen). The

second phenomenon is mostly difficult to correct : it is the movement of the arc inside the nozzle

implying fluctuations of the arc voltage and the plasma flow.

Several studies have analysed the dynamic behavior of DC plasma gun for binary gas mixtures

Ar/H2 or Ar/He, for which the range of variation of gas composition is too limited. Indeed, it is well known that a high hydrogen content results in a quicker erosion of the electrodes, and helium content must to be high enough to melt particles. Ternary gas mixtures, reducing electrode erosion, permit the use of a large range of gas composition, which can be adapted to the required properties of the deposit. Nonetheless, the use of Ar/He/H2 gas mixtures results in a modification of the plasma/particule tranfert, flow and stability of the gun working, which can result in a modification of the atmosphere engulfment in the plasma jet.

This paper presents an investigation of the influence of the plasma spraying parameters on the

fluctuations of arc root, arc voltage and plasma flow. The measurements were carried out for various

ternary gas mixtures of argon, helium and hydrogen (Table I).

Table I : Plasma spraying conditions.

The fluctuations of the arc voltage and plasma flow are controlled respectively by the analysis

of the voltage signals and plasma velocity. This latter is measured by using the analysis of the luminous fluctuations of the plasma flow. In the potential core, the plasma jet velocity was determined from the light fluctuations which originate in the arc root instabilities. These fluctuations are supposed to propagate at the flow velocity. The measurement method is closely connected to a time-of-flight method.

The measurement of arc voltage fluctuations are based on the analysis of the arc restrike

behavior in DC plasma torches. The sampling rate is 10 µs/point (100 kHz), higher than the arc root

frequency (4 to 20 kHz).

Experiments were carried out using a Plasma Technik F4VB gun with a 6-mm nozzle diameter

and a vortex injection of the plasma forming-gas in the arc zone.

- From the arc voltage signals, the effect of total mass gas flow rate, gas composition and arc current on the static behavior of the plasma spray torch was studied :

- the average arc voltage

- the arc root frequency

- the jump amplitude which is the deviation between the minimum and maximum voltage

within an oscillation

From an adimensional analysis, a correlation between the frequency, and the plasma spraying

parameters was established, showing that it is similar to the plasma velocity correlation established

previously.

- Concerning the analysis of the dynamic behavior of the torch, for higher total gas mass flow rate (>5.10-4 kg/s), only the restrike mode was observed, due to the major influence of the mass flow rate (which depends on the gas composition and the plasma temperature) on the arc movement. The

influence of hydrodynamic forces on arc root is predominant.

For lower total gas mass flow rate (< 5.10-4 kg/s), several modes of torch working have been

observed for a low gas mass flow rate, explained by the significative influence of electromagnetic

forces on the arc root :

- an oscillating mode (Fig. 2)

- a restrike mode (Fig. 3)

- an intermediate mode (Fig. 4).

|

|

|

Figure 2 : Arc voltage signal (in volt) in the oscillating mode

(Ar/He/H2 gas mixture : 50/40/10 vol. % - 27 slm - 320 A).

|

Figure 3 : Arc voltage signal (in volt) in the restrike mode

(Ar/He/H2 gas mixture : 40/40/20 vol. %.- 27 slm - 600 A).

|

| |

Figure 4 : Arc voltage signal (in volt) in the intermediate mode (mélange Ar-He-H2 : 37/55,6/7,4 % vol. - 27 l/mn - 320 A)

|

This article have shown that the restrike mode is obtained when the hydrodynamic or/and

electromagnetic forces, and thickness of the cold layer surrounding the arc column are sufficient to

produce the jump of the arc attachment.

The experiments pointed out the fact that at a low gas mass flow rate, with the increase of the

anode erosion, the restrike mode disappears. Indeed some preferential arc attachment points are

created on the anode surface, and thus the hydrodynamic forces are no longer sufficient to produce

arc jump.

The analysis of the plasma velocity fluctuations gives us information on the stability of the gun

working. It appears that this stability is higher in the case of higher constricted arc column and a

mass flow rate.

PARTICLE BEHAVIOR IN A FLUCTUATING PLASMA JET

J.H. Park*, J. Heberlein*, E. Pfender*, Y.C. Lau**, J. Ruud**, and H.P. Wang**

*Department of Mechanical Engineering, University of Minnesota, Minneapolis, MN 55455

**General Electric Research and Development, Niskayuna, NY 12301

ABSTRACT

Plasma jets generated by conventional d.c. plasma torches reveal more or less severe temporal

fluctuations due to fluid dynamic effects and the effect of anode arc root motion inside the plasma

torch. As shown in the frames of Fig. 1, the fluctuations cause the jet characteristics to

continuously change with time during torch operation. They, in turn, alter trajectories and

temperature histories of the particles which are injected into the fluctuating plasma jet. The

resultant particle behavior is somewhat different from the one obtained under steady-state plasma

conditions. Although there is clear experimental evidence for the existence of such fluctuations1,

previous simulations of plasma jets usually neglected such fluctuations, because of the difficulties

associated with the analytical description of their transient and three-dimensional characteristics.

Moreover, it is time-consuming to simulate the fluctuations using a transient three-dimensional

code, even with high-speed parallel supercomputers. Any realistic comparison of experimental data

with analytical predictions, however, requires that such fluctuations should be considered in the

modeling efforts, because experimental data will usually provide time-averaged and fluctuation-averaged values.

In this paper analytical/numerical studies of the particle behavior in plasma jets are reported, taking

these plasma fluctuations into account in a simplified manner without developing a transient three-

dimensional code. In general, the arc root moves back and forth in axial direction, and it also

rotates along the cylindrical anode surface with a fluctuation frequency in the order of several kHz.

The plasma plume, therefore, experiences axial and radial fluctuations according to the arc root

motion. The rotational fluctuations are approximated by radial fluctuations assuming that the arc

root attaches itself on the anode surface without any preferred tangential direction. The radial

fluctuations can be simply included in the numerical model for simulating plasma jets by the time-

averaging method2.

In the time-averaging method the steady-state solutions for plasma jets are obtained using

conventional two-dimensional codes such as the LAVA code3. The steady-state plasma variables

such as velocity and enthalpy are allowed to fluctuate in radial direction with specified fluctuation

distance and frequency. By averaging those fluctuating variables over a fixed fluctuation period,

new time-averaged plasma conditions can be found, leading to plasma variables comparable to the

experimental data. However, before considering particle injection into the plasma under time-averaged conditions which are obtained using the time-averaging method, we have to consider

particle residence time. The residence time of powder particles in the plasma jet is typically longer

or of the same order of magnitude as the fluctuation period. This implies that the particles are

actually interacting with a fluctuating plasma rather than with an axisymmetric time-averaged

plasma. In order to take these fluctuation-dependent interactions between plasma and particles into

account in the model, the steady-state plasma solutions are allowed to fluctuate in radial direction

and the powder particles are injected into the fluctuating plasma jets.

The re-strike mode of torch operation results in plasma fluctuations in axial direction as well as in

radial direction. The axial fluctuations manifest themselves through voltage fluctuations. The

voltage variation leads to changes of the input power and the plasma jet characteristics vary with

the imposed input power. The voltage variations directly affect the boundary conditions at the

torch exit. The maximum axial velocity and temperature values change with the voltage

fluctuations since we assume that the profile shapes are fixed at the torch exit. In this paper, the

voltage is assumed to fluctuate sinusoidally with the same frequency as the radial fluctuations.

Figure 2 presents plasma temperature distributions which are varying with time under the influence

of both axial and radial fluctuations during one fluctuation period. A single particle or multiple

particles are injected into these axially and/or radially fluctuating plasma jets to study the effects of

plasma fluctuations on particle behavior.

CONCLUSION

The effects of the plasma fluctuations on the motion and temperature histories of a single particle

and multiple particles are investigated in the present paper. Comparisons of particle data based on

steady-state plasma conditions obtained without considering the fluctuations show large deviations

from the corresponding experimental data. On the other hand, the particle data obtained with

consideration of axial and radial plasma fluctuations reveal reasonable agreement with

measurements. The simple features of the proposed analytical way of taking into account the

plasma fluctuations can be easily applied to conventional plasma and plasma-particle interaction

models.

REFERENCES

- S. A. Wutzke, "Conditions governing the symptomatic behavior of an electric arc in a

superimposed flow field," Ph.D. Dissertation, University of Minnesota, 1967.

- J. H. Park, "Numerical modeling of multi-component plasma jets," M.S. Thesis, Department of

Mechanical Engineering, University of Minnesota, 1998.

- J. D. Ramshaw and C. H. Chang, "Computational fluid dynamics modeling of multicomponent

thermal plasmas," Plasma Chem. Plasma Proc. 12, 299 (1992).

Fig. 1 Pictures of a fluctuating plasma jet taken by a laser strobe camera

Fig. 2 Temperature distributions of a plasma jet fluctuating in axial and radial directions

|